Pumps are generally divided into two types – vane pump and positive displacement pump.

1) Vane pump – constantly adding energy to the liquid to increase its speed.

An example of vane pump is centrifugal pump, which uses kinetic energy to increase the velocity energy and potential energy of liquid through the conversion of impeller.

Impeller design can be divided into radial flow, mixed flow or axial flow according to its hydraulic geometry.

The regeneration pump is a centrifugal pump, but its impeller rotates in an annular channel with inlet and outlet openings.

2) Positive displacement pump (reciprocating or rotary). In a positive displacement pump, energy is periodically added to the liquid by directly applying a force to one or more movable volumes of liquid.

Examples of positive displacement pumps are diaphragm pumps or rotary cam pumps.

Diaphragm pumps use a combination of the reciprocating action of a rubber or PTFE diaphragm and a suitable check valve to pump liquid.

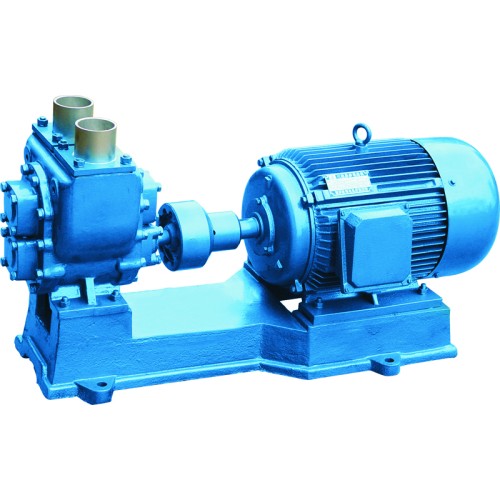

Rotary pump is the most widely used positive displacement pump, which is used to pump viscous liquids such as oil, syrup and paint.

Reciprocating pump is also one of the oldest pump types. They consist of pistons that move back and forth in the cylinder.

What is the purpose of the pump?

Pumps move or circulate fluids or gases in a piping system that may include heat exchangers, valves, mixers, monitoring equipment and instruments.

Email: [email protected]

Email: [email protected]

WhatsApp: +8613777832123

WhatsApp: +8613777832123